Fancy Pack, is a full-service Printing and Packaging Company that offers a full suite of creative packaging solutions and services all under one roof. We adhere to the highest standards of quality and continuously invest in the latest technology at all levels of development, from the pre-press stage to the final execution to deliver our client's world-class printing and packaging solutions.

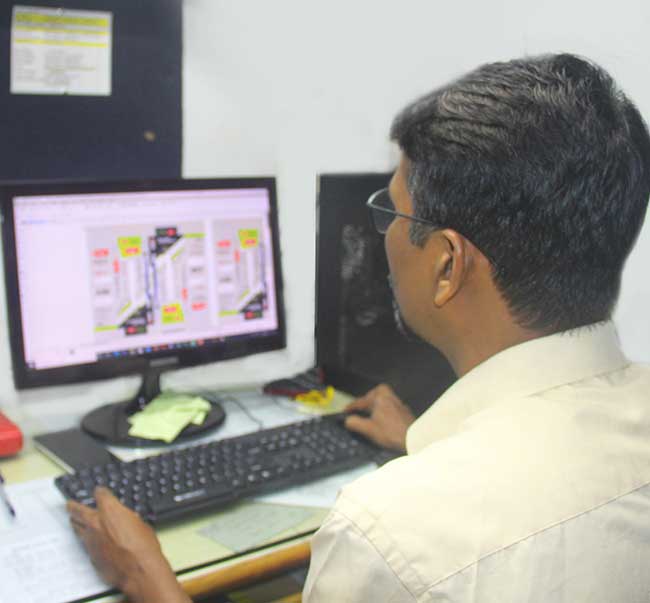

Pre-Press

- This is the preliminary stage in the printing process

- Before the job can be printed, the document must be converted to "plates"

- Processing artwork into pre-press materials demands technical perfection and accurate judgement of colours, screens, dots and lines

- At Fancy Pack we use Computer-To-Plate (CTP) technology to eliminate the film stage and hence producing cleaner images with crispier colours

- We ensure that there is intensive planning in this stage to avoid any wastage and to ensure best printing results to set our customers apart from its competitors

Press

- This is the stage where the actual production starts

- Our high-end five-Colour HEIDELBERG Presses are capable of printing on all conventional paper boards and metalized polymer (MetPAT) substrate

- The in-line coating facilities in these presses ensure nimble production

- Our machines are equipped with fully programmed CPCs to maintain the consistency of the job even for future orders

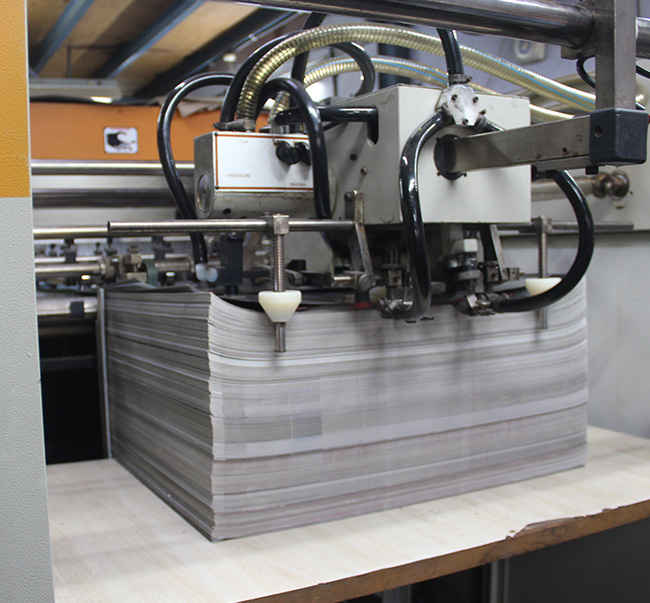

Post-Press

While some printing jobs are delivered as printed, most printing is usually not complete until it is converted into a “finished” product. Our post-press services can be categorized as:

Window Patching, Binding, Embossing, Foiling, Gold Leafing/Gilding, Glitter UV, Grain UV, Spot UV, Matte/Gloss Lamination, Structure Finish, Varnishing.

There is stringent in-process testing and inspection to ensure a quality product that meets and exceeds all our client’s requirements, in time.